Warehouse Execution System

Autonomous Mobile Robots: Collaborative Deployment in Intralogistics

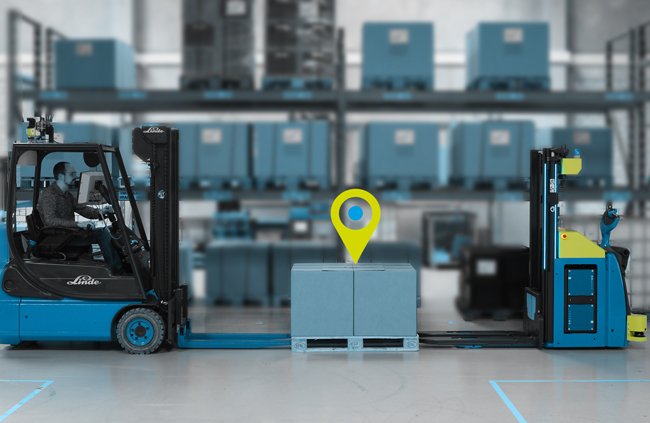

The ideal solution for seamless goods, material, and pallet tracking in collaborative operation with forklifts.

✓ Collaborative deployment for seamless interlogistics flow

✓ Seamless identification and tracking of pallets using digital twin algorithms

✓ Flexible, scalable, and future-proof

Locate forklifts in real time and dispatch them to the next task

IdentPro’s fully autonomous transport robots (Autonomous Mobile Robots = AMR) revolutionize intralogistics. They are designed to meet the demands of collaborative deployment with manual forklifts. The AMRs serve any source/sink points and enable scan-free, continuous goods or pallet tracking—optionally integrated into the Warehouse Execution System. These can be used stand-alone or integrated into overall warehouse optimization through the Warehouse Execution System.

True autonomous navigation including obstacle avoidance

24/7 operation possible due to Li-Ion battery technology

Picks up pallets from ground even in slanting position

Safety technology for the detection of persons and obstacles (CE approved)

Digital Twin:

Collaborative use

Today’s autonomous or automated vehicles are not yet capable of performing all intralogistical operations. Collaborative use is therefore ideal to realise the full potential of the warehouse. Due to our digital twin algorithms, our AMRs enable the seamless identification and tracking of pallets, regardless of the vehicle type. This unique feature allows mixed fleets of manual and autonomous vehicles to be used optimally, depending on the intended application.

Automation:

Mobility through 24/7 service

The future of intralogistics is digital and autonomous. IdentPro supports this transformation by providing flexible and scalable solutions such as contour-based positioning, digital twin technology, and autonomous pallet transport for sustainable optimization.

With the automation opportunities IdentPro offers, you are well-equipped to respond to the threat of the skilled labor shortage: