Case Study: ELA Container

Mobile space and building solutions

Full real-time transparency — no scanning required

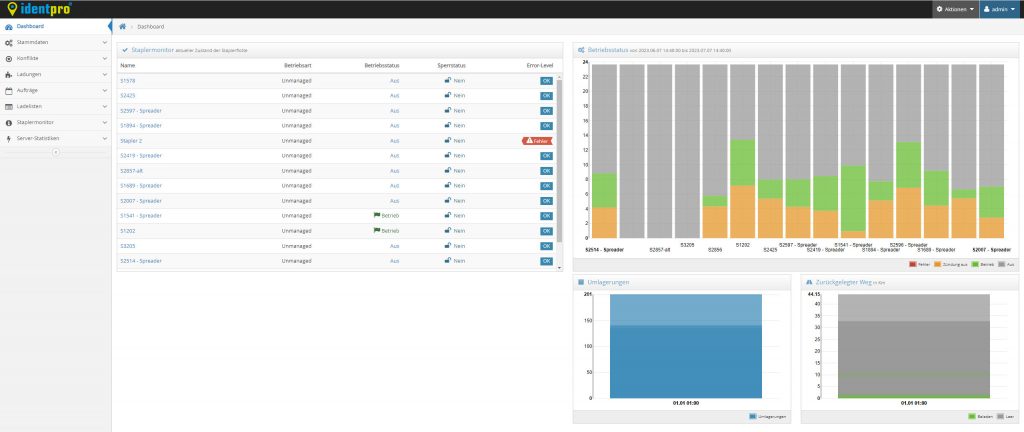

To locate every building container with to-the-second, centimeter-level accuracy, ELA Container relies on IdentPro’s Warehouse Execution System (WES). The goal was to eliminate manual administration and search times, automate postings, and create a continuously transparent inventory overview. The result: a search-free material flow from the yard to truck loading.

ELA Container is a family-owned specialist for mobile space and building solutions for rent or purchase. The company serves a broad range of industries: from construction, office, and education (e.g., schools and daycare) to retail, events, and custom solutions. Headquartered in Haren (Ems), Lower Saxony, ELA delivers projects across Germany and internationally. The rental fleet comprises around 60,000 containers, with a presence spanning 18 locations worldwide.

ELA Container at a glance

| Industry | Mobile space and building solutions |

| Headquarters | Haren (Ems), DE |

| Company size | approx. 1,400 employees |

| Solution used | IdentPro Warehouse Execution System (WES) |

| Primary benefits | Reduced search times for building containers; faster loading |

| Presence | 18 locations worldwide |

Initial Situation

At the start of the project, ELA Container managed its large rental fleet largely manually and without end-to-end system support. This led to high search and administrative effort because inventories and locations could not be verified in real time. The variety of solution types and frequent relocations across the expansive outdoor yard further slowed processes; truck loading incurred waiting times.

Concretely, this meant:

Project constraint that emerged: For comprehensive coverage in the outdoor yard, pure Wi-Fi proved unreliable (stacking up to 9 m, robust container walls), so the network was switched to LTE early on.

Project Objective

The aim was a search-free warehouse with 100% real-time transparency across all container movements from production to loading. To achieve this, the material-handling vehicles were retrofitted with LiDAR and IoT sensors so that positions and movements could be captured with centimeter-level precision in seconds. Based on this data, IdentPro’s WES created a digital twin with visualization and a 3D forklift guidance system that intelligently distributes transport orders, optimizes routes, and respects priorities. Postings are automated and scan-free; all relevant information appears directly on the truck terminal.

To ensure reliable capture across the expansive outdoor yard, especially with triple stacking up to 9 m, the existing Wi-Fi infrastructure was upgraded to LTE. In parallel, employees were trained and the use of real-time data was anchored in day-to-day operations. The WES operates seamlessly in outdoor (and indoor) areas and connects to ERP/WMS via standard interfaces.

Requirements

Results & Benefits

With IdentPro’s WES, ELA Container now operates search-free: inventories and locations are reliably available in real time at any moment. Orders can start without back-and-forth, detours are eliminated, and employees make decisions based on consistent data.

Our specialists can now focus on what matters and no longer waste time searching!

— Michael Gerdes, ELA Container

Loading has accelerated dramatically: processing a truck dropped from around 2 hours to about 10 minutes. This significantly reduces waiting times, and yard and loading areas become available again much faster. Productivity rises because routes, order distribution, and vehicle utilization are optimized based on data. The 3D guidance system prioritizes orders, consolidates trips, and supports even fleet utilization. The solution also delivers planning certainty and scalability: in productive use since September 2022, the setup serves as a robust blueprint for additional sites.

Facts & Figures

Case Study Download

For even more exciting insights into the ELA Case Study, you can download it here.