Building materials are the foundation of any construction project. However, without efficient building material logistics, projects are delayed, costs are high, and storage errors are frequent. Modern warehouses in the building materials industry are therefore increasingly relying on digital solutions and automation: With real-time digital twins and laser localization, logistics specialists in the building materials industry can keep track of every item, reduce returns, and ensure that building materials are in the right place at the right time.

Building Materials in Motion: Ensuring Smooth Logistics

Building materials are the foundation for modern living, working, mobility, and infrastructure. Without them, there would be no buildings, bridges, roads, or technical facilities. This makes building materials logistics a crucial cornerstone for ensuring that construction projects run smoothly, on time, and economically, and that everything flows smoothly on the construction site. Without efficient logistics, there is a risk of delays, cost increases, and bottlenecks. The building materials industry has some special requirements for smooth warehouse operations because the goods are heavy and bulky. From bricks to natural stones, wood, cement bags, and steel beams, they are often stored in large outdoor areas and exposed to the weather and dirt. Traditional barcodes and RFID solutions are difficult to use because not every item can be labeled or easily scanned. The goods are often not stackable and are frequently relocated. Added to this are high turnover rates and tight time windows.

Cost Drivers in Building Materials Logistics: Search Times, Errors, and Returns

Keeping track of everything in the building materials warehouse under these conditions poses a number of challenges for logistics specialists. If it is unclear what is stored where and in what quantity, this leads to long search trips, incorrect deliveries, and inventory discrepancies. Inefficient processes not only have consequences within the warehouse: construction projects come to a standstill, production processes are delayed, and high follow-up costs are incurred. There is a risk of contractual penalties, damage to reputation, and dissatisfied customers. Inefficient processes in building material warehouses also often lead to a high return rate, which results from a combination of logistical, organizational, and construction site-specific factors. Construction projects are subject to frequent changes due to weather conditions, construction delays, or decisions made by building owners. Similar products are also frequently confused, or sensitive materials are damaged during transport, making returns necessary. In addition, many building materials come in countless variations in terms of color, size, or surface. The high product complexity increases the error rate when selecting and ordering. Returns cost time, money, and human resources, as they must then be checked, cleaned, and re-stored or even disposed of.

Key Challenges in Building Materials Logistics:

Automating Warehouse Processes with Real-Time Location Systems

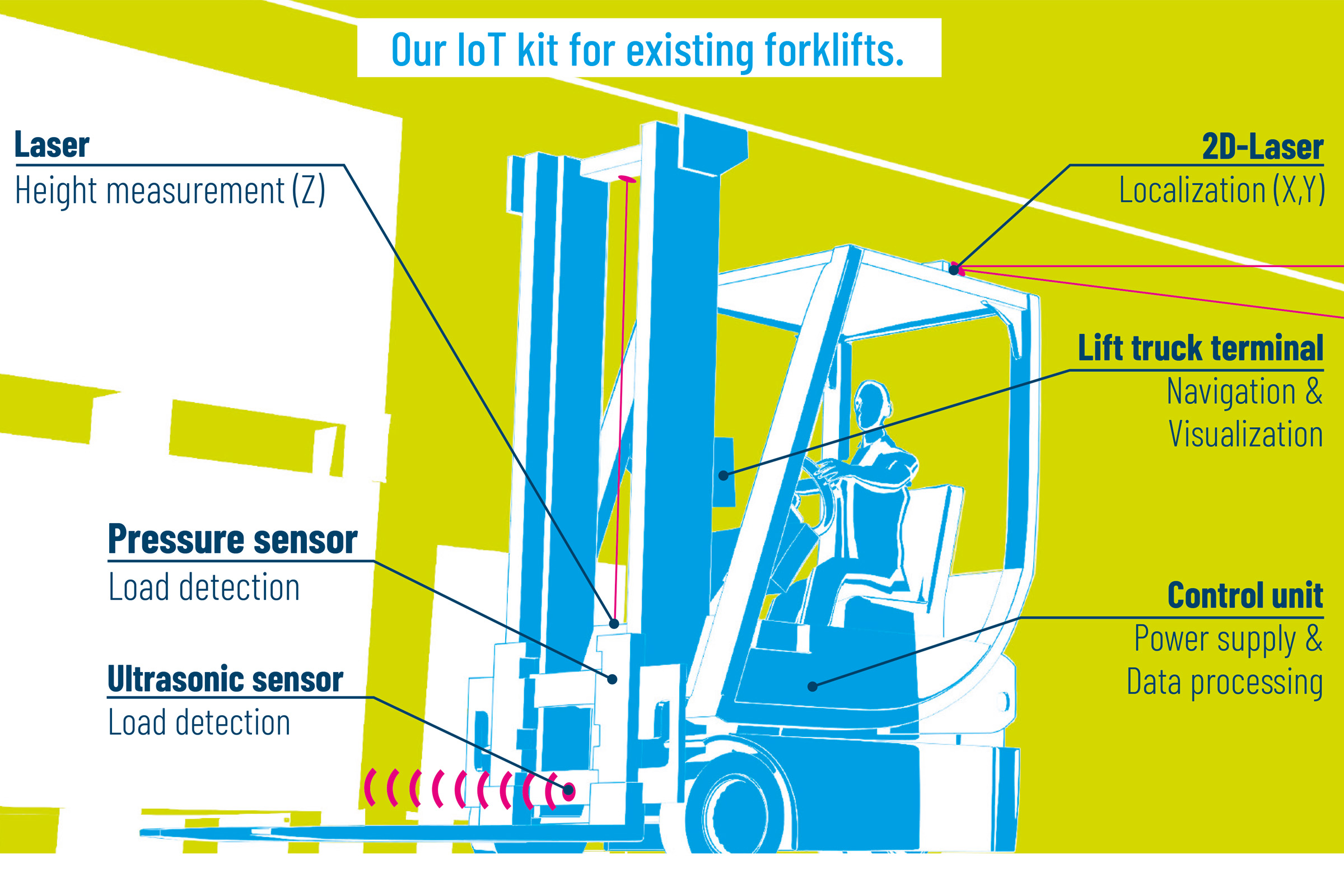

To optimize warehousing in the building materials industry, more and more warehouses are tackling these challenges with digitalization and innovative IoT technology, such as IdentPro’s Warehouse Execution System. With a real-time location system (RTLS) in the warehouse, all material movements can be automatically tracked and located in real time, without manual scanning or additional labeling. This allows warehouse processes to be optimized. Each building material is mapped in the digital twin, so it is always clear where each material is located, in what quantity, and in what form.

Seamless integration into existing ERP systems, such as SAP, gives dispatchers and warehouse managers full transparency and allows them to efficiently manage even short-term changes or returns.

The Digital Twin: Key to Efficient Warehouse Operations

The key to efficient warehouse management in the building materials industry is the digital twin: a virtual 3D model that displays all storage locations, inventories, and goods movements in real time. This is made possible by LiDAR sensors attached to forklift trucks and other industrial trucks. They continuously scan the environment, compare the positions with the 3D warehouse model, and automatically track every movement of pallets, cement bags, steel beams, and other items. Building material warehouses that introduce the digital twin in real time using laser localization achieve one thing above all else: full transparency of their inventory and an overview of all warehouse movements. This means that in a digitized warehouse, every item can be located at any time, search times and storage errors are avoided, and inventory is taken virtually incidentally, as stocks are updated automatically and continuously. Deliveries are correct and complete, even with a high degree of variety and short-term changes. Simple batch management allows every batch to be traced in the system. This reduces the return rate in building materials logistics because mix-ups or incorrect deliveries are avoided. Dispatchers can optimize storage space and make the best use of storage locations. Real-time data allows them to respond flexibly to construction progress, schedule changes, or weather conditions. Digital location tracking in the warehouse ensures faster throughput times, lower process costs, and higher customer satisfaction.

Benefits of the Digital Twin in Building Materials Warehouses:

3D model of all storage spaces, driveways, and material areas

No renovation work is necessary for implementation. As a rule, stable Wi-Fi coverage and sensors on the vehicles are sufficient. This is followed by digital mapping of the warehouse. The entire site is scanned once to create a precise 3D model of all storage locations, traffic routes, and material areas. Based on this, IdentPro’s Warehouse Execution System builds the digital twin: a real-time representation of the inventory and all warehouse movements. In the next step, the system is connected to existing ERP solutions such as SAP EWM or solutions specialized in building materials, such as those from OGS at Hagemeister, so that master datasets, orders, and inventory levels are synchronized at all times. From this moment on, every warehouse movement is automatically captured without any manual scanning. As soon as the forklift picks up a pallet, a stack of cement bags, or a steel beam, the system registers the position and automatically links it to the item in the digital twin. Every warehouse movement is tracked digitally, and when the item is set down, the new position is immediately transferred to the 3D warehouse model.

How Real-Time Localization Optimizes Warehouse Operations:

Forklift trucks are equipped with sensors and the site is then digitally connected via Wi-Fi. The entire storage area is scanned once to create a precise 3D model of all storage locations, traffic routes, and material areas. Based on this, the warehouse execution system creates a digital twin that automatically records every movement in the warehouse, regardless of whether the goods come from production, a distributor, or as returns. Upon arrival at the warehouse, goods and geo-coordinates are linked and can thus be tracked at any time. Forklift drivers receive driving and storage instructions directly at the terminal, while the system transfers the position of the goods to the 3D warehouse model in real time.

Optimized Warehouse Management: ROI in Just 12 to 24 Months

In a modern building materials warehouse equipped with real-time IoT technology, it is clear at all times where each material is located and in what quantity it is available: without any manual scanning, labeling, or data entry in the warehouse. Warehouse errors are avoided and warehouse management is optimized. Even transfers or short-term relocations are automatically recorded. The transition to live operation usually takes only a few weeks, as no structural modifications to the warehouse itself are necessary. The benefits are obvious: IdentPro customers report a return on investment within just 12 to 24 months, because search times, storage errors, and return rates are significantly reduced, while delivery quality is noticeably improved.