Optimized materials management: When analogue empties management is automated – Modern IoT technology as a solution for an industry-specific challenge.

In the dynamic world of the beverage industry, flexibility, efficiency and technological innovation are essential. The empties module, an industry-specific extension of the Warehouse Execution System, makes a significant contribution to the transformation of warehouse logistics in the beverage industry.

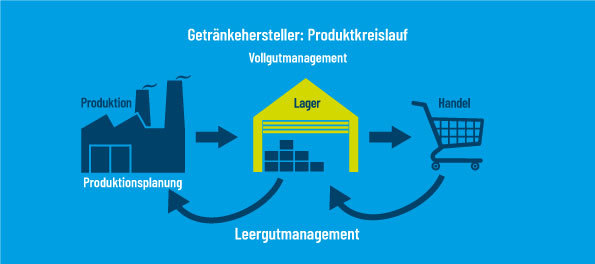

Empties management: a key element of the beverage industry

The return and refilling of empties is of central importance for breweries and beverage producers. The challenge, however, is to make this process seamless in order to optimize production planning and effectively reduce costs. Insufficient labeling and traceability of empties, complicated by different return sources such as retailers, often lead to manual, error-prone processes and loss of sales.

Challenges in the beverage industry

Production planning:

Without precise knowledge of the available empties, it is difficult to plan production or filling efficiently. There is a risk that not enough bottles will be available, which can lead to production stoppages.

Personnel expenses:

Unclear information about the empties stock requires increased effort when searching for the required empties. Employees have to go through potentially long processes to find the empties they need, which affects productivity.

Innovation in practice

Empty pallets have no unique identification (SSCC) and cannot be easily recorded. With IdentPro’s Warehouse Execution System, entire inventories can be localized and controlled in real time. The solution has a unique application for the challenges of the beverage industry. To this end, the existing industrial trucks are equipped with IoT kits to record all stocks / movements / orders live. The AI-based software generates a digital twin in real time and intelligently controls driving orders.

What does SSCC stand for?

The SSCC (Serial Shipping Container Code) is an international standard code that is used to identify shipping units (such as pallets, cartons or containers) in the supply chain. It enables each shipping unit to be uniquely identified worldwide and thus facilitates tracking and administration in logistics.

Each SSCC is a unique 18-digit numeric code. This is made up of an extension digit, a GS1 company number, a consecutive serial number and a check digit. The GS1 company number is a number assigned by the GS1 system that identifies the company that created the shipping unit.

By using the SSCC, companies can track their shipping units more efficiently, automate incoming and outgoing goods and improve the accuracy of their supply chain processes. The code is usually applied to the shipping unit in the form of a barcode so that it can be easily scanned and processed in IT systems.

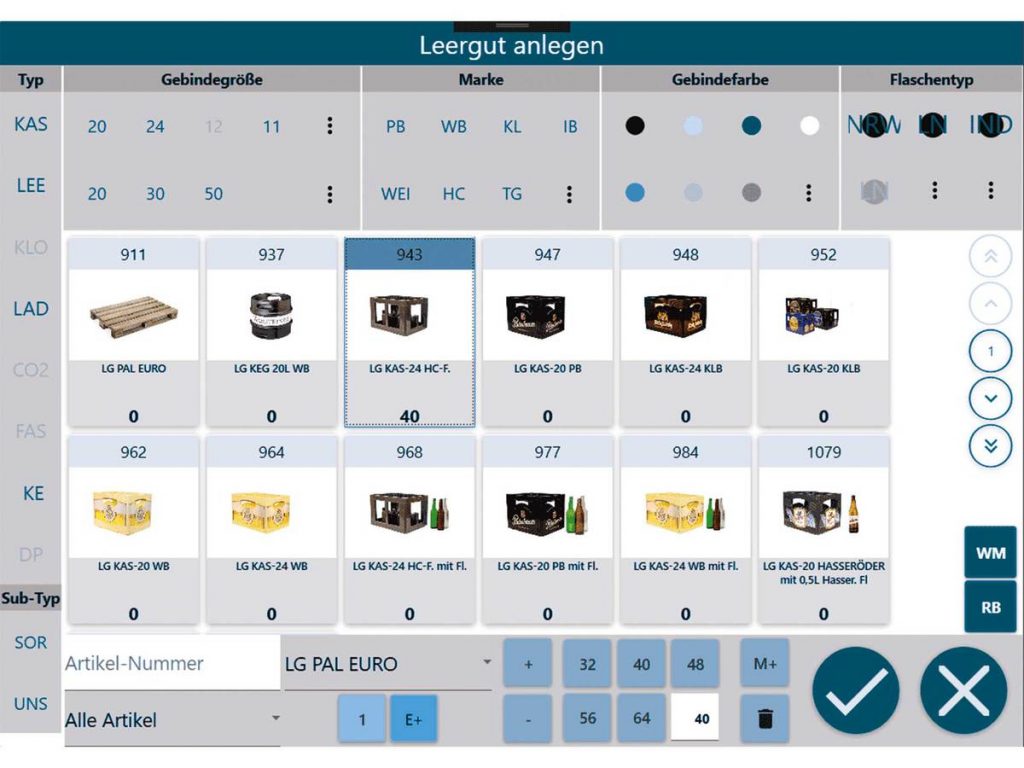

The empties module: Automation of empties handling

Empties – without barcodes or other identification – can now be tracked fully automatically. The forklift driver picks up an unknown pallet of empties and the stock levels are recorded via the software interface. The forklift driver uses a quick filter to pick up pallets of empties with just a few clicks. The entry window asks how many pallets have been recorded. An optional image search can then be used to easily specify the type of bottle recorded – without having to scan or leave the vehicle. The empties pallet is recorded in the software and assigned a virtual number. Once connected to the system, the goods are automatically tracked and controlled.

Advantages at a glance

- Simple recording & operation

- Drivers no longer have to search for empties

- Planning reliability in production

- Valid inventory information leads to full transparency

- Can be connected to any ERP system such as SAP EWM via an interface

Conclusion

The challenges of empties management can have a negative impact on production planning and efficiency. The introduction of automated tracking systems can help to fully exploit this potential. Efficient empties management is not only a sign of operational efficiency, but also an important factor for customer satisfaction and the economic success of a company.

International success stories in the beverage industry

Success stories from companies such as Warsteiner, Bitburger, Refresco and Asahi underline the effectiveness of IdentPro’s customized technology, which not only increases productivity but also leads to a sustainable transformation of logistics processes.

In an era where efficiency, sustainability and digital transformation are key, IdentPro is at the forefront of this movement, demonstrating how digitalization and intelligent automation are achieving actionable success in the real world of the beverage industry.